Diamond [PCD and CVD] cutting tools are used to machine hard non ferrous materials.

Advantages of Synthetic Diamond Tools:

- Increased tool life

- Ability to cut a wide range of materials

- Resists chipping in interrupted cuts

- High material removal rates

- Reduced cycle time

- Improved part size control

- Improved part finish

- Lower scrap rates

- Reduced downtime

- Reduced per part machining costs

- Less inspection time

We can supply PCD diamond custom made cutting tools per specification for your milling, turning, drilling, counterboring, chamfering and porting applications. We can also recondition and repair existing PCD tools.

Array of Diamond Cutting Tools, PCD and CVD

Recommended Diamond Applications:

Nonferrous Metals

- Aluminum

- Silicon-Aluminum Alloys

- Brass Alloys

- Bronze Alloys

- Copper

- Copper Alloys

- Lead Alloys

- Manganese Alloys

- Presinserted Tungsten Carbide

Abrasive Nonmetals

- Carbon

- Ceramics

- Fiberglass Composites

- Graphite

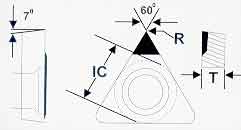

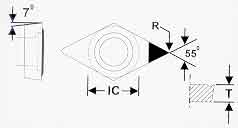

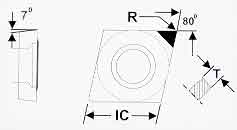

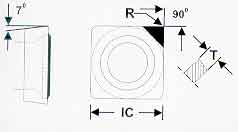

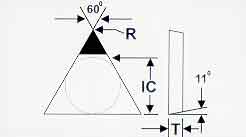

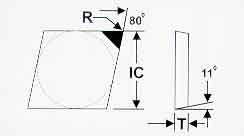

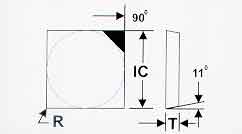

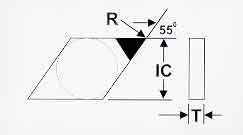

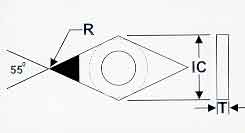

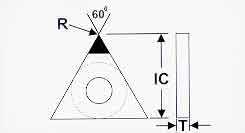

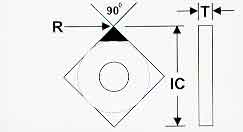

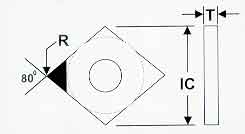

Flat tools for turning and milling

| Product Number | I.C. | T | R | Product Shape |

|---|---|---|---|---|

| TCMW 2(1.5)1 | 1/4 | .094 | 1/64 |  |

| TCMW 3(2.5)1 | 3/8 | .156 | 1/64 | |

| TCMW 3(2.5)2 | 3/8 | .156 | 1/32 | |

| DCMW 2(1.5)1 | 1/4 | .094 | 1/64 |  |

| DCMW 3(2.5)1 | 3/8 | .156 | 1/64 | |

| CCMW 2(1.5)1 | 1/4 | .094 | 1/64 |  |

| CCMW 3(2.5)1 | 3/8 | .156 | 1/64 | |

| CCMW 3(2.5)2 | 3/8 | .156 | 1/32 | |

| SCMW 3(2.5)1 | 3/8 | .156 | 1/64 |  |

| SCMW 3(2.5)2 | 3/8 | .156 | 1/32 | |

| TPG-221 | 1/4 | 1/8 | 1/64 |  |

| TPG-321 | 3/8 | 1/8 | 1/64 | |

| TPG-322 | 3/8 | 1/8 | 1/32 | |

| TPG-431 | 1/2 | 3/16 | 1/32 | |

| TPG-432 | 1/2 | 3/16 | 1/32 | |

| CPG-421 | 1/2 | 1/8 | 1/64 |  |

| CPG-422 | 1/2 | 1/8 | 1/32 | |

| CPG-423 | 1/2 | 1/8 | 3/64 | |

| SPG-321 | 3/8 | 1/8 | 1/64 |  |

| SPG-322 | 3/8 | 1/8 | 1/32 | |

| SPG-421 | 1/2 | 1/8 | 1/64 | |

| SPG-422 | 1/2 | 1/8 | 1/32 | |

| SPG-632 | 3/4 | 3/16 | 1/32 | |

| DNG-432 | 1/2 | 3/16 | 1/32 |  |

| DNG-433 | 1/2 | 3/16 | 3/64 | |

| DNMA-322 | 3/8 | 1/8 | 1/32 |  |

| DNMA-323 | 3/8 | 1/8 | 3/64 | |

| TNMA-322 | 3/8 | 1/8 | 1/32 |  |

| TNMA-323 | 3/8 | 1/8 | 3/64 | |

| SNMA-322 | 3/8 | 1/8 | 1/32 |  |

| SNMA-323 | 3/8 | 1/8 | 3/64 | |

| CNMA-432 | 1/2 | 3/16 | 1/32 |  |

| CNMA-433 | 1/2 | 3/16 | 3/64 |

Application/Machining Guidelines

| Material | Operation | Surface Speed (Ft./Min.) |

Feed Rate (In./Rev.) |

|---|---|---|---|

| Aluminum < 12% SI | Finish Turning | 2000-6000 | .003-.008 |

| Rough Turning | 2000-6000 | .005-.020 | |

| Finish Milling | 1000-10000 | .001-.005 | |

| Rough Milling | 800-6000 | .005-.012 | |

| Aluminum >12% SI | Finish Turning | 1000-3000 | .003-.008 |

| Rough Turning | 1000-2000 | .005-.015 | |

| Finish Milling | 1000-3300 | .001-.005 | |

| Rough Milling | 1000-2500 | .005-.012 | |

| Metal Matrix Composites | Finish Turning | 1000-2400 | .004-.010 |

| Rough Turning | 800-1500 | .005-.020 | |

| Finish Milling | 1400-2000 | .005-.010 | |

| Rough Milling | 1000-1400 | .008-.015 | |

| Bi-Metal Aluminum Cast Iron | Finish Milling | 800-1000 | .004-.006 |

| Sintered Tungsten Carbide < 16 CO | Finish Turning | 50-100 | .004-.010 |

| Sintered Tungsten Carbide > 16 CO | Finish Turning | 75-125 | .004-.010 |

Round tools for porting, counterboring, drilling and chamfering

We can:

- Alter/Modify PCD Tipped Tools

- Manufacture Tools from Part Print

- Manufacture Tools from Tool Print

- PCD Tool Conversion

- PCD Tool Reconditioning

- PCD Tool Redesign