PCBN Cutting Tools are used to machine hardened ferrous materials.

nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;nbsp;

- Excellent for finishing and semi roughing of gray cast iron and powder metal

- Regrindable for additional cutting edges

- Can be used in milling operations

|

Highlights

- Excellent for finishing and semi roughing of gray cast iron and powder metal

- Regrindable for additional cutting edges

- Can be used in milling operations

|

|

|

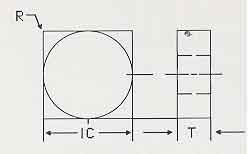

Highlights

- Indexable-multiple corners

- Eliminates debrazing potential

- Excellent roughing tools

- Excellent inserts for milling

|

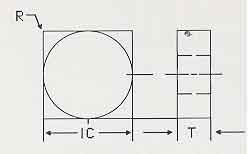

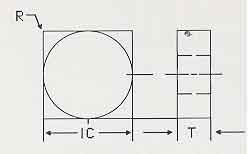

| Full-Face Indexable BZN Inserts |

|---|

| Product Shape |

Product Number |

IC |

T |

R |

6000 |

8100 |

|---|

|

BRNG-32 |

3/8 |

1/8 |

- |

• |

• |

| BRNG-42 |

1/2 |

1/8 |

- |

• |

• |

| BRNG-43 |

1/2 |

3/16 |

- |

• |

- |

|

BSNG-322 |

3/8 |

1/8 |

1/32 |

• |

• |

| BSNG-323 |

3/8 |

1/8 |

3/64 |

• |

• |

| BSNG-432 |

1/2 |

3/16 |

1/32 |

• |

- |

| BSNG-433 |

1/2 |

3/16 |

3/64 |

• |

- |

|

BTNG-322 |

3/8 |

1/8 |

1/32 |

• |

• |

| BTNG-323 |

3/8 |

1/8 |

3/64 |

• |

• |

|

• Standard / Inventory

All standard inserts supplied with a 20° x .004" chamfer.

|

|

|

Highlights

- Lowest initial cost

- Excellent for hardened steel turning

- Eliminates regrinding

|

|

| Application/Machining Guidelines |

|---|

| Material |

Operation |

Grade |

Surface Speed

(Ft./Min.) |

Feed Rate

(In./Rev.) |

Depth of Cut

(In.) |

|---|

|

Gray Case Iron

(180-270 BHN)

|

Turning |

BZN-6000 |

2000-4000 |

.006-.925 |

.005-.100 |

| Milling |

BZN-6000 |

2000-4000 |

.006-.012 |

.010-.100 |

|

Hard Cast Iron

(>400 BHN)

|

Turning |

BZN-6000 |

250-500 |

.006-.025 |

.005-.100 |

| Milling |

BZN-6000 |

400-800 |

.006-.012 |

.010-.100 |

|

Hardened Steel

(>45HRC)

|

Rough Turning |

BZN-6000/8100 |

220-350 |

.006-.025 |

.030-.100 |

| Finish Turing |

BZN-8100 |

350-450 |

.004-.008 |

.004-.030 |

| Superalloys |

Turning |

BZN-6000 |

550-800 |

.004-.012 |

.004-.100 |

| Milling |

BZN-6000 |

700-1000 |

.004-.008 |

.004-.050 |

| Sintered Iron |

Turning |

BZN-6000 |

300-600 |

.004-.010 |

.004-.050 |

| Milling |

BZN-6000 |

400-800 |

.004-.008 |

.004-.050 |

| Tool Steels* |

Turning |

BZN-8100 |

325-650 |

.004-.012 |

.004-.012 |

|

Alloy Steels Surface Hardened*

|

Turning |

BZN-8100 |

260-650 |

.004-.012 |

.004-.012 |

| Tool/Alloy Steels** |

Turning |

BZN-8100 |

220-350 |

.006-.025 |

.006-.025 |

|

* Continuous to moderately interrupted cuts

** Surface scale or heavily out of round/interrupted workpiece

|

|

|