Diamond tipped commutator tools are specialized for machining copper motor commutators either in dedicated commutator turning machines or engine lathes. They are available in either synthetic or natural diamond. We offer new, re-sharpened and re-tipped tools.

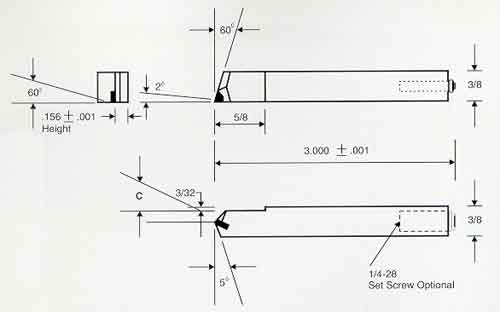

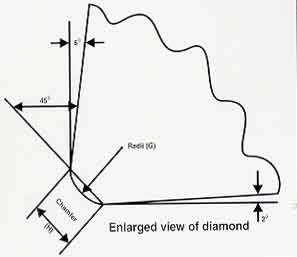

Radius and Chamfer Commutator Tools

- All diamond tools are polished to a micro mirror finish.

- Ultra-sharp cutting edges, free of chips.

- Tool geometry engineered to give you the micro finish you need.

- A cleaner cutting tool that leaves no chips

- Longer lasting, more finished parts per tool.

- More relaps per tool, to help control your tooling costs.

- Complete relap, reset, and repair program restores your tools to their original condition.

- All tools are held to the tighest tolerances in the industry.

- All tools are optically inspected to insure the highest quality and workmanship.

| Tool Style | C | G | H |

|---|---|---|---|

| MM or FF * 375-R Radius Tooling | 20° | .010 | - |

| 20° | .015 | - | |

| 20° | .020 | - | |

| 25° | .010 | - | |

| 25° | .015 | - | |

| 25° | .020 | - | |

| MM or FF * 375-F Chamfer (Flat) Tooling | 20° | - | .010 |

| 20° | - | .015 | |

| 20° | - | .020 | |

| 25° | - | .010 | |

| 25° | - | .015 | |

| 25° | - | .020 |

- FF for Synthetic Diamond

- MM for Natural Diamond

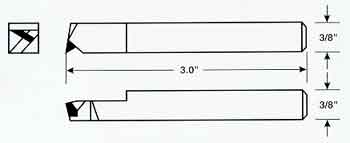

Skiving Commutator Tools

- Cleans the slots of the commutator without drag over.

- Gives a uniform cut with a minimum working pressure.

- A combination cheer type action and skiving cut.

- Non-interrupted cut reduces shock on the diamond because the diamond is engaged across the bars.

- Large included angle for strength and long life of the tool.

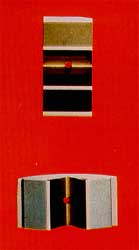

Synthetic Diamond Bearings

- Diamond bearings are lapped to a mirror finish to eliminate shaft galling.

- Diamond bearings offer longer life at a comparable cost to carbide bearings.

- The need for lubrication is eliminated or greatly reduced with diamond bearings. No more copper chips soaked with oil sticking to everything on your lathe.

- Precise armature positioning with diamond bearings helps you maximize the potential of your diamond tools.

- Longer bearing life means your tool center line height will always be correct.

Array of diamond cutting & dressing tools